Emerging technologies have driven the performance boundaries of the glass centrifuge tubes, offering improved acceleration rates and greater throughput of samples. Programmable features and touchscreens give users more control over every operation stage. Temperature-controlled glass centrifuge tubes in delicate biological processes guarantee specimen stability over extended cycles. Maintenance-friendly designs and auto-diagnostic programs minimize downtime. The adaptability of next-generation glass centrifuge tubes devices ensures compatibility with any sample type, ranging from microfluidic volumes to industrial suspensions, making it a vital tool in scientific and engineering studies.

The utilitarian uses of glass centrifuge tubes have expanded due to technological advancements. It is utilized in pharmacology to ensure high-purity drug formulations. It is utilized in biotechnology for protein crystallization and vaccine synthesis. The extractive industry utilizes glass centrifuge tubes to separate valuable minerals from raw mixture. In classrooms, it facilitates laboratory demonstrations of fluid flow. Even in the restoration of paintings, expert glass centrifuge tubes facilitate cleaning and stabilizing delicate pigments. The applicability of glass centrifuge tubes to so many different fields is evidence of its utility as an industrial and scientific agent for material separation.

Future trends show that glass centrifuge tubes will become more intelligent, miniaturized, and green. Researchers envision systems capable of learning for themselves and optimizing their performance from previous data results. Integration within digital laboratory workflows will render operations, from sample entry to data reporting, more seamless. Increased automation will free researchers from manual monitoring, allowing more focus on analysis. In industrial processes, glass centrifuge tubes will have a role in cleaner production through the reduction of waste and energy usage. It is a step toward smarter scientific instrumentation that adapts to the challenges of technology.

Continuous cleaning and routine checkup maintain a glass centrifuge tubes in good working order. The rotor must be carefully inspected for distortion or corrosion because even small flaws can result in unbalance. Users should clean the interior chamber with a soft cloth at the end of each run to remove residues. Electrical and mechanical components must undergo regular checks for proper alignment and accuracy of speed. Periodic calibration at specified intervals maintains measurement precision. By implementing a formal maintenance regime and strict compliance with manufacturer instructions, the glass centrifuge tubes is dependable upon repetitive application.

Scientific and industrial applications use the glass centrifuge tubes for its ability to differentiate between mixes with high precision. It relies on the force of centrifugal, which pushes particles off center, leading to density stratification. The method is vital in research, medicine, and engineering. From cell constituents separation to the separation of liquids, glass centrifuge tubes make many analytical and production processes easier. Newer models focus on minimizing vibration, maximizing balance, and the use of smart sensors to monitor data in real time. All these advancements have made glass centrifuge tubes faster, safer, and more efficient than before.

Q: What safety measures are important when operating a centrifuge? A: Always ensure the rotor is balanced, the lid is securely closed, and safety locks are engaged before starting operation. Q: What types of centrifuges are available? A: Common types include micro, benchtop, refrigerated, and ultracentrifuges, each suited for specific laboratory or industrial applications. Q: Why is balancing samples important for a centrifuge? A: Imbalanced samples can cause vibration, noise, and mechanical stress, potentially damaging both the rotor and the instrument. Q: What materials can be processed in a centrifuge? A: A centrifuge can handle liquids, suspensions, and even some emulsions, depending on its speed and rotor type. Q: How long can a centrifuge run continuously? A: Run time depends on the model and workload—most can operate from a few minutes up to several hours under proper temperature control.

The delivery bed is well-designed and reliable. Our staff finds it simple to operate, and patients feel comfortable using it.

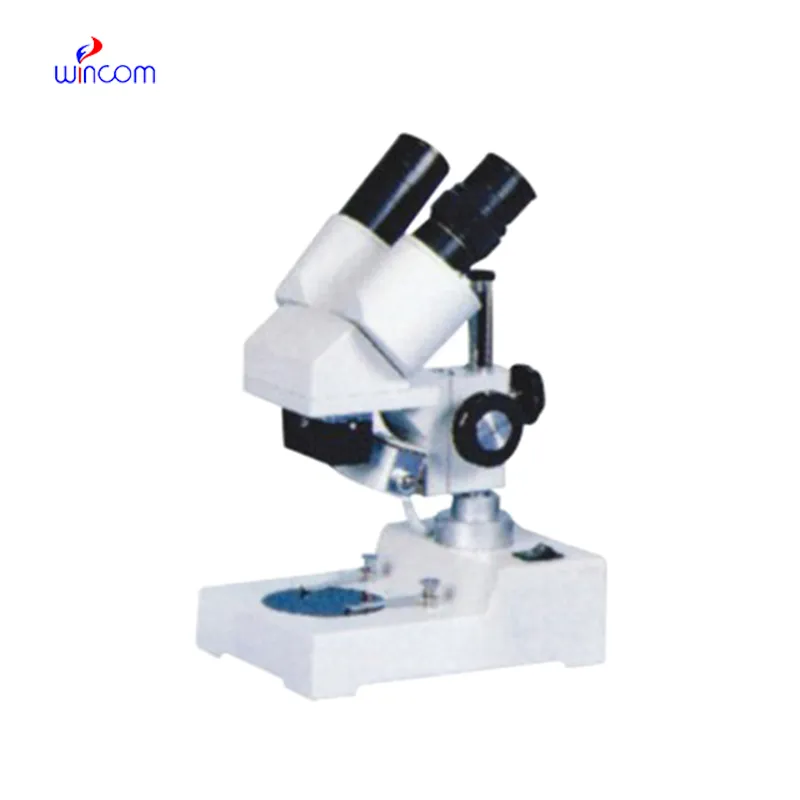

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

I’d like to inquire about your x-ray machine models. Could you provide the technical datasheet, wa...

We are planning to upgrade our imaging department and would like more information on your mri machin...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China