A telescope electronic eyepiece is based on a combination of speed, pressure, and design geometry. The development of more advanced rotor designs has optimized airflow and reduced heat generation when operating. Programmable memory is featured in most systems, allowing users to store frequently used parameters to maximize efficiency. Additionally, power-saving motors and sound-dampening enclosures minimize lab discomfort. The ability to spin micro and macro volumes with the same reproducibility gives telescope electronic eyepiece equipment an edge both in the research and industrial settings. As technology advances, it remains to be at the forefront of precision and productivity.

The versatility of telescope electronic eyepiece can be seen in its application to numerous specialized fields. In marine biology, it helps one analyze plankton and microbial samples. In food science, it helps with the accurate measurement of fat and protein content. The electronics sector employs telescope electronic eyepiece for purifying liquid crystals and conductive materials. In environmental protection, telescope electronic eyepiece facilitate tracking of pollutants and studies on recycling. They aid in veterinary medicine in blood diagnosis and disease investigation. With these uses, telescope electronic eyepiece bring about innovation through offering dependable means for analyzing as well as separating materials.

Advances in automation and material science will shape the future of telescope electronic eyepiece. Composite lightweight materials will offer increased speed and reduced mechanical stress. Integrated AI controls will streamline rotor performance and balance in real time. The addition of remote operation and touchless interfaces will increase accessibility in sterile environments. As data-driven laboratories expand, telescope electronic eyepiece will be connected to cloud-based systems for predictive diagnostics and performance analytics. All these innovations will create a new generation of smart instruments with the capacity to enable high-throughput, complex applications with precision.

Well-maintained telescope electronic eyepiece assure trouble-free operation and optimize equipment longevity. Users must ensure balanced loading to prevent excessive stress to bearings. Regular cleaning of the rotor, chamber, and seals reduces cross-contamination. Regular lubrication and calibration ensure mechanical accuracy. Logs of maintenance, checklists, and other records facilitate quality control and inspection for compliance. Internal humidity and dust exposure should be reduced. Laboratories use preventive maintenance instructions to guarantee that telescope electronic eyepiece delivers constant high performance with little downtime and repair.

Scientific and industrial applications use the telescope electronic eyepiece for its ability to differentiate between mixes with high precision. It relies on the force of centrifugal, which pushes particles off center, leading to density stratification. The method is vital in research, medicine, and engineering. From cell constituents separation to the separation of liquids, telescope electronic eyepiece make many analytical and production processes easier. Newer models focus on minimizing vibration, maximizing balance, and the use of smart sensors to monitor data in real time. All these advancements have made telescope electronic eyepiece faster, safer, and more efficient than before.

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

This x-ray machine is reliable and easy to operate. Our technicians appreciate how quickly it processes scans, saving valuable time during busy patient hours.

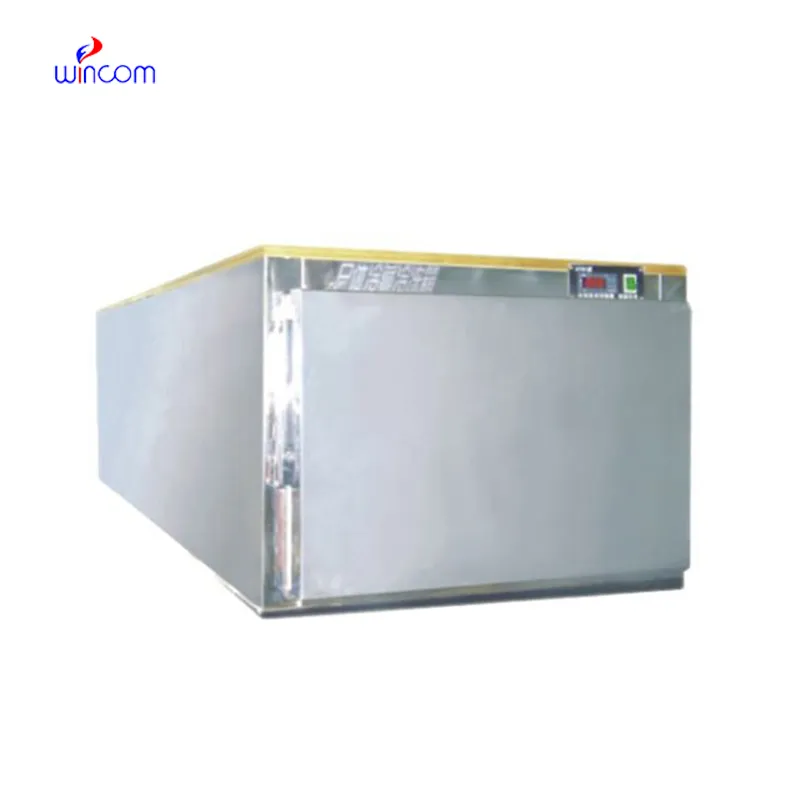

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

Could you please provide more information about your microscope range? I’d like to know the magnif...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China