Crafted specifically for precision, the predator 212 centrifugal clutch is additionally improved by digital and mechanical enhancements. Intelligent balancing systems automatically eliminate unbalanced loads, improving performance as well as safety. Materials such as reinforced polymers and high-grade aluminum are becoming standard in rotor production, reducing wear and maximizing life in operation. Real-time sensors of temperature and speed offer feedback for reliable results. These developments not only improve separation efficiency but also allow for the achievement of stringent laboratory standards. With increasing research needs, predator 212 centrifugal clutch technology develops further to ensure better reliability and reproducibility.

The diversity of predator 212 centrifugal clutch applications shows its diversity to modern technology. Aerospace engineers utilize it to check the material properties under intense centrifugal stress. Nanotechnology utilizes it to segregate particles at micro and nanolevel for analysis and manufacturing purposes. Hospitals rely on predator 212 centrifugal clutch for testing, ensuring accurate plasma and serum analysis. Food processing industries utilize it to ensure product purity and uniformity. Additionally, educational laboratories employ predator 212 centrifugal clutch in teaching and experimentation, whereby students learn fundamental physics, chemistry, and biology concepts through hands-on demonstration.

Advances in automation and material science will shape the future of predator 212 centrifugal clutch. Composite lightweight materials will offer increased speed and reduced mechanical stress. Integrated AI controls will streamline rotor performance and balance in real time. The addition of remote operation and touchless interfaces will increase accessibility in sterile environments. As data-driven laboratories expand, predator 212 centrifugal clutch will be connected to cloud-based systems for predictive diagnostics and performance analytics. All these innovations will create a new generation of smart instruments with the capacity to enable high-throughput, complex applications with precision.

Accurate maintenance ensures that predator 212 centrifugal clutch functions properly and safely in the long term. Regular cleaning after use prevents creation of residues that affect rotation balance. Users should inspect rotors from time to time for signs of wear and have them replaced once such signs are noticed. Calibration and balancing checks should be on a predetermined schedule. All seals and gaskets should remain in place to prevent leakage during use. Storage of equipment is to be in a stable, dry location. Proper maintenance not only preserves function but also safeguards the accuracy of every experimental result.

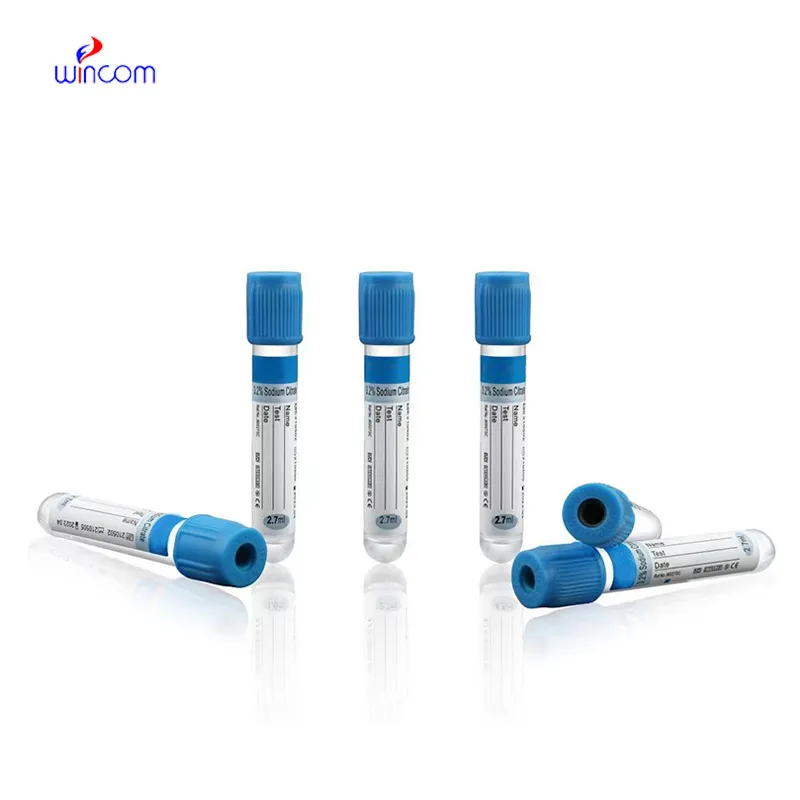

A predator 212 centrifugal clutch is a universal gadget designed to separate parts in a mixture through sheer spinning power. A predator 212 centrifugal clutch operates through the principle of sedimentation, in which heavier particles move outwards and lighter particles remain at the center. Employed within laboratories, clinics, and industry in general, a predator 212 centrifugal clutch may be utilized to separate materials such as blood plasma, proteins, and chemical reagents with accuracy. Modern predator 212 centrifugal clutch exist in various forms, from benchtop to industrial types and ultracentrifuges, all for specialized applications. They are accurate and reproducible, a necessity in production and research.

Q: How is a centrifuge different from a mixer or shaker? A: Unlike mixers or shakers that blend materials, a centrifuge separates components based on density through high-speed rotation. Q: What power requirements does a centrifuge need? A: Most benchtop centrifuges use standard AC power, while industrial units may require higher voltage for greater speed and capacity. Q: Can a centrifuge be used in pharmaceutical production? A: Yes, centrifuge equipment is widely used to purify chemical compounds and biological materials during drug manufacturing processes. Q: How do I prevent vibration during operation? A: Ensure all tubes are evenly loaded, rotors are clean, and the machine is placed on a stable, level surface. Q: What is the lifespan of a centrifuge? A: With regular maintenance and proper usage, a centrifuge can last for many years while maintaining consistent performance.

This ultrasound scanner has truly improved our workflow. The image resolution and portability make it a great addition to our clinic.

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re interested in your delivery bed for our maternity department. Please send detailed specifica...

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China