The function of a activate the centrifuge dead space structure depends entirely on its integrity. Manufacturers now use advanced dynamic balancing techniques to minimize vibration and increase lifespan. High-torque motors give smooth rotational power, and safeguards such as locking lids and imbalance sensors protect the user and sample from injury. In specialized lab arrangements, refrigerated activate the centrifuge dead space maintain constant temperatures for biological samples. Miniaturized forms are also gaining ground, sacrificing space savings for speed and accuracy. These trends show the ongoing coming of age of activate the centrifuge dead space engineering into versatility and reliability.

The utilitarian uses of activate the centrifuge dead space have expanded due to technological advancements. It is utilized in pharmacology to ensure high-purity drug formulations. It is utilized in biotechnology for protein crystallization and vaccine synthesis. The extractive industry utilizes activate the centrifuge dead space to separate valuable minerals from raw mixture. In classrooms, it facilitates laboratory demonstrations of fluid flow. Even in the restoration of paintings, expert activate the centrifuge dead space facilitate cleaning and stabilizing delicate pigments. The applicability of activate the centrifuge dead space to so many different fields is evidence of its utility as an industrial and scientific agent for material separation.

Sustainability, connectivity, and accuracy will be the areas of future evolution of activate the centrifuge dead space. Instruments will be made with sustainable materials and energy-efficient drives to minimize their carbon footprint. Real-time monitoring of data through cloud-based systems will facilitate real-time troubleshooting and process optimization. Portable versions will enhance accessibility in remote- or field-based studies. In pharma and biotech, activate the centrifuge dead space will ramp up production with intelligent automation. As technology continues to evolve, activate the centrifuge dead space will remain at the center of scientific innovation, bridging the gap between mechanical performance and digital intelligence.

Well-maintained activate the centrifuge dead space assure trouble-free operation and optimize equipment longevity. Users must ensure balanced loading to prevent excessive stress to bearings. Regular cleaning of the rotor, chamber, and seals reduces cross-contamination. Regular lubrication and calibration ensure mechanical accuracy. Logs of maintenance, checklists, and other records facilitate quality control and inspection for compliance. Internal humidity and dust exposure should be reduced. Laboratories use preventive maintenance instructions to guarantee that activate the centrifuge dead space delivers constant high performance with little downtime and repair.

activate the centrifuge dead space is a piece of mechanical equipment that separates simple mixtures into differentiated parts by utilizing quick spinning. It functions by employing centrifugal force, which expels heavier elements and brings lighter elements closer towards the axis. This principle makes crucial work possible in microbiology, pharmaceuticals, and materials science. High-speed models can achieve exceptional separation accuracy in mere minutes. Modern activate the centrifuge dead space feature digital interfaces, temperature control, and advanced safety locks to ensure operation. They are so fast and versatile that they are a must-have asset for any laboratory or manufacturing plant.

Q: How is a centrifuge different from a mixer or shaker? A: Unlike mixers or shakers that blend materials, a centrifuge separates components based on density through high-speed rotation. Q: What power requirements does a centrifuge need? A: Most benchtop centrifuges use standard AC power, while industrial units may require higher voltage for greater speed and capacity. Q: Can a centrifuge be used in pharmaceutical production? A: Yes, centrifuge equipment is widely used to purify chemical compounds and biological materials during drug manufacturing processes. Q: How do I prevent vibration during operation? A: Ensure all tubes are evenly loaded, rotors are clean, and the machine is placed on a stable, level surface. Q: What is the lifespan of a centrifuge? A: With regular maintenance and proper usage, a centrifuge can last for many years while maintaining consistent performance.

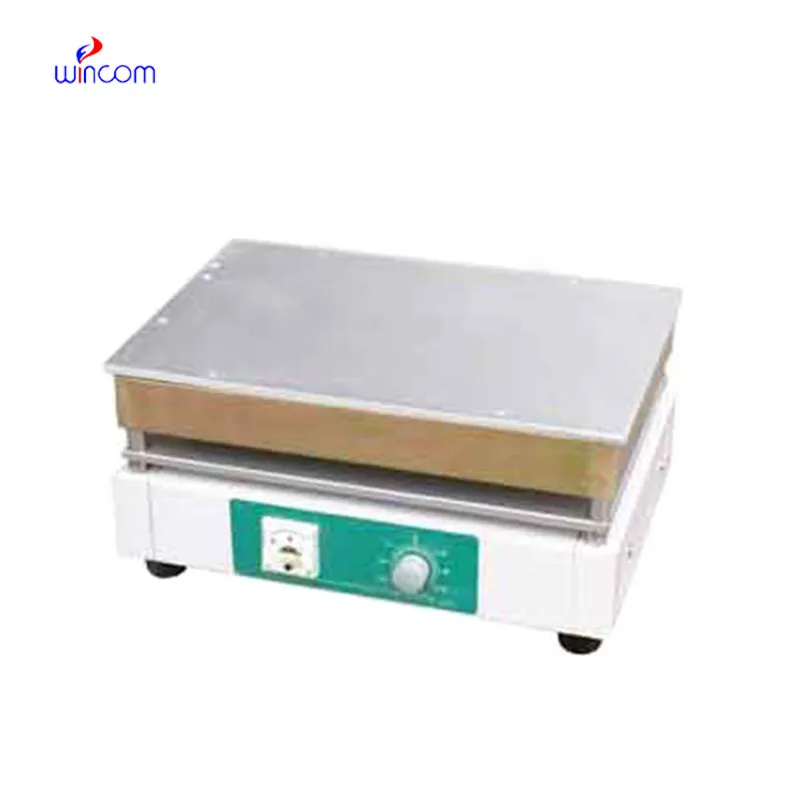

The water bath performs consistently and maintains a stable temperature even during long experiments. It’s reliable and easy to operate.

We’ve been using this mri machine for several months, and the image clarity is excellent. It’s reliable and easy for our team to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

I’d like to inquire about your x-ray machine models. Could you provide the technical datasheet, wa...

We are planning to upgrade our imaging department and would like more information on your mri machin...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China